Here are some more early 1500 characteristics:

This large diameter pulley was used from the beginning of production until December 1962. The diameter was changed to reduce the speed of the generator.

This early fan housing looks like any Type 3 fan housing at first glance, but a closer look reveals no thermostat flaps or linkage. VW didn't add a thermostat to the Type 3 engine until August '63.

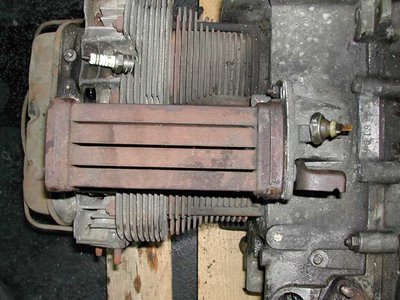

Right side cooling tin used through August '62.

Left side tin through August '62. The nut near the top between the plugs is a mount for the oil cooler.

With the left side tin removed the oil cooler is visible. The early Type 3 engine used a cooler that's almost identical to the Beetle cooler except for the added mounting stud on the left side that's visible in the previous image. The cooler is attached to the case via an intermediate bracket that also holds the oil pressure switch and a bracket for the carb return spring. Other than the oil pressure switch these parts were all discontinued in August '62.

The '62 oil cooler used four Type 1 seals. The good news is they're easy to find; the bad news is that there are four seals that can potentially leak. Here are the first two seals.

And with the bracket removed the other two seals can be seen.

Here's the right side head showing the 90° intake port. I wasn't happy to find a broken fin on #2 (upper left).

That's an early head alright.

With the head removed and turned over the long rocker studs can be seen. On most cars the long rocker studs have been replaced by the later short studs that were introduced in August '64. I'm going to try to keep them, but I may have to replace them with short studs if they give me any trouble.

Here are the right side valves. Aside from a lot of sludge and carbon things look surprisingly good. No dropped valve seats (which I expected) or broken valves, and no obvious cracks. Good news, since these heads are really hard to find.

#2 and #1. Again, a lot of carbon but otherwise nothing too bad. I expected to see some obvious damage to #2, but so far nothing. At this point the sudden compression loss was still a mystery.

The long block went off to the machinist, and I had some parts cleaning ahead of me.

No comments:

Post a Comment